Collaboratively designed food waste dewatering

Our Dehydra dewatering system can reduce the volume of food waste by up to 80% and its weight by 50%

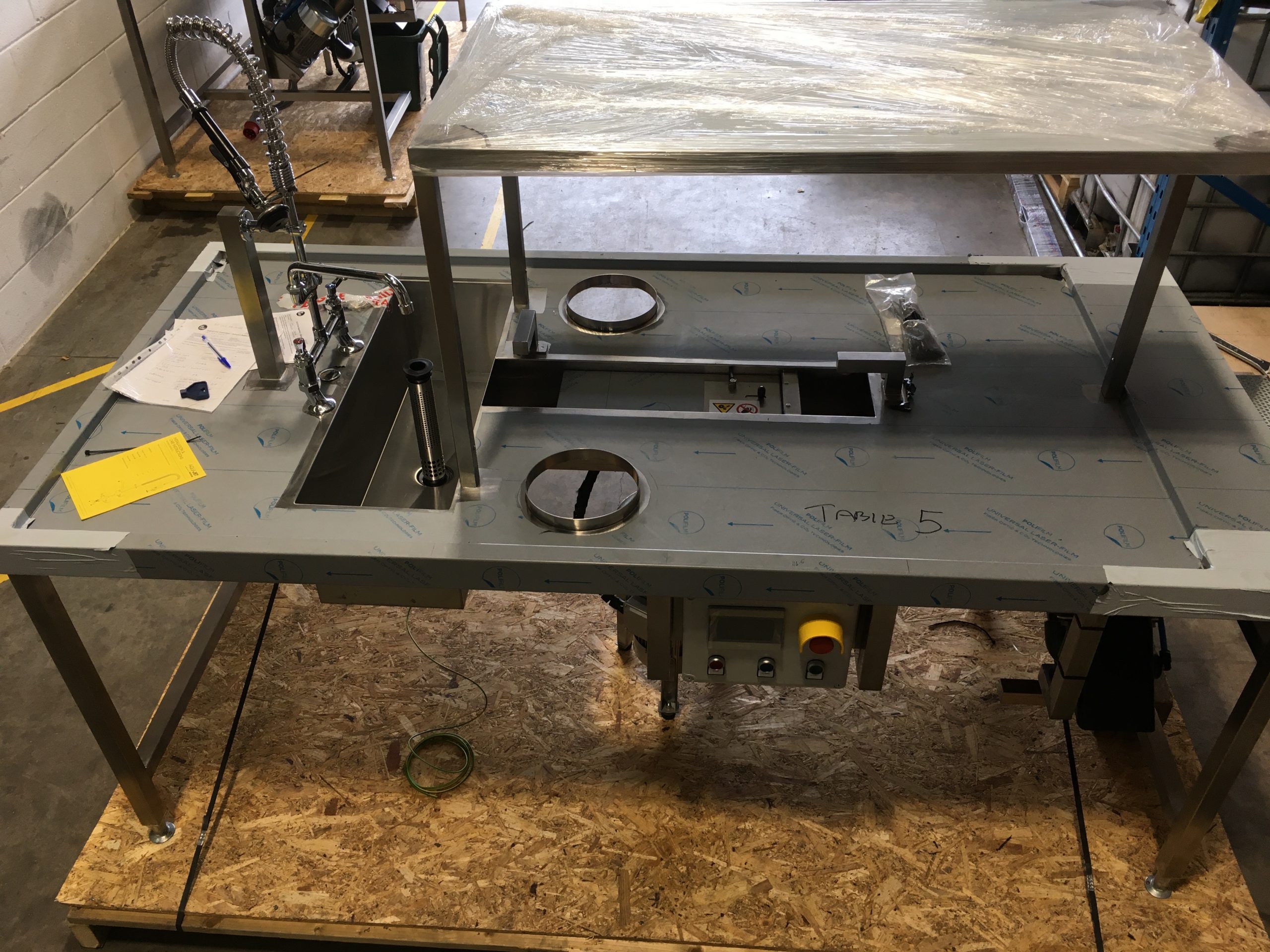

Located next to a commercial dishwasher, this unit is designed to receive trays and wastes from trolleys at one end and then step by step allow the waste to be removed, the crockery stacked, rinsed and washed. With a full width collection trough the Workstation enables operation from both sides to improve flexibility and reduce processing time.

We understand that one size doesn’t always fit all, and we’ve been commissioned to design and manufacture a number of Bespoke dewatering units like these workstations for our clients. If your project has specific requirements, contact our helpful team to discuss how we can help.

Dehydra Workstation

- Description

- Specification

- Spec Sheet

Our Dehydra workstation and bespoke dewatering units provide a more tailored platform for the effective separation and minimisation of high-volume, high-moisture food waste. And this process can save organisations a significant amount of money in off-site disposal costs – not to mention vastly cutting down their carbon footprint, by reducing the amount of vehicle movements needed.

Clients who have commissioned Bespoke Bench units have had us come up with some pretty unique configurations – some of which decant the waste at head height so that much larger wheeled bins can be filled. Requests for customised shapes and sizes are also very common, as is double-sided working benches to allow more than one operator to process the waste.

How does the Dehydra food waste dewatering system work?

Operatives feed the food waste into the hopper – where it is ground into small particles by the food waste disposer (FWD). The resulting material is then pumped from the FWD into the hydro-extractor – where an auger and 1.5mm-holed fine-mesh screen separate the liquid from the ground food waste.

This process ensures that all solids are captured effectively, leaving the excess liquids such as sauces, soups, and juices to be disposed of in the main sewer.

Once the food waste has been processed, the system automatically self-cleans the hydro-extractor screen, ensuring the efficiency of the dewatering unit is maintained.

>Specification

Dimensions – standard unit (mm) | Subject to design requirements |

|---|---|

Water connections | Pressure: 3 Bar ± 1 Bar |

Water consumption (flow rate) cold water | 10 litres per minute |

Water consumption (flow rate) hot water | 3 litres per cleaning cycle |

Discharge size (mm & inches) | 50 / 2” |

Capacity (food waste) per minute / hour (kg) | 12 / 700 |

Weight (kg) | Subject to design |

Decibels (dB) | 63-70 |

Electrical phase | 3 |

Motor voltage (v) | 380-415 |

Motor frequency (Hz) | 50 |

Motor kilowatt – Total (kW) | 4.4 |

Amps | 16 |

Electrical connection | Flying leads to be hard-wired to site connection Power Supply to the Dehydra must be protected by a 30mA RCD. |

Cutlery saver | As standard |

Air-Break | Fitted as standard |